CNC Beam Drill Line Birmingham

CNC Beam Drill Lines are space-efficient beam processing solutions. They require a minimum of 70ft by 9ft floor space. This makes it perfect for smaller fabricators and fabricators who have limited space. Many CNC Beam Drill Line installations are located outside, which allows for more fabricator space.

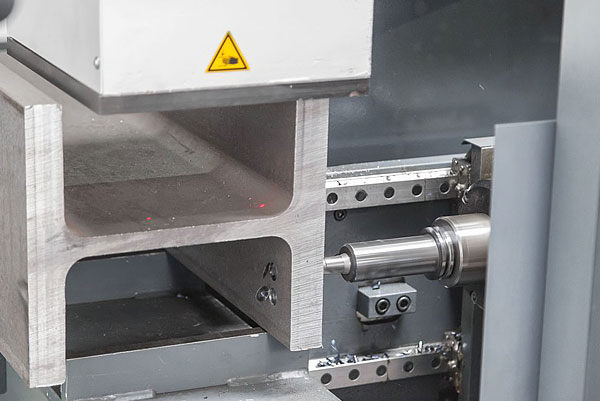

An attachment that marks 4-axis locations eliminates human error during manual layout. Even after painting blasting or galvanizing, the part information is still retained.